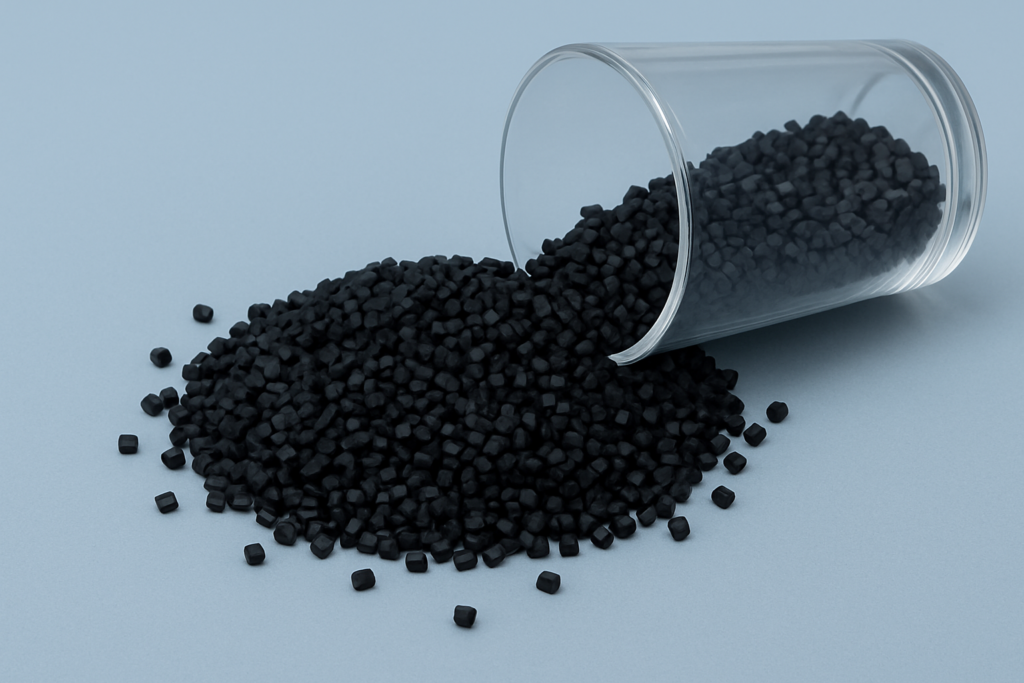

Polyamide holds a strategic position in today’s materials industry. This engineering thermoplastic polymer, better known under its commercial name Nylon, has established itself for decades as a reference solution across numerous industrial sectors. Its outstanding versatility, remarkable mechanical properties, and ease of processing make it an essential material, despite the environmental challenges it raises.

This article offers a comprehensive overview of polyamide: from its technical definition to eco-responsibility issues, through its multiple industrial applications and the innovations shaping its future. We will analyze why this material remains indispensable in today’s economy while examining the solutions being developed to reduce its environmental footprint.

Polyamide (PA) is a thermoplastic polymer made of small repeating units linked by strong amide bonds. This structure gives it high strength, elasticity, and good heat resistance. It is formed through a chemical reaction called polycondensation, where two types of molecules — diamines and diacids — assemble while releasing water. This process creates long, regular chains that provide both toughness and flexibility.

For certain grades such as PA6, an ingredient called caprolactam is used. Heated to open its structure, it transforms into long polyamide chains. The molten polymer is then cooled and stretched (drawing) to align the chains, further strengthening its resistance. Fibers are then washed, dried, and wound into spools ready for weaving or molding.

Although highly efficient, this production process relies on petroleum derivatives and consumes significant amounts of energy, raising environmental concerns.

Today, thanks to its properties, polyamide is widely used in fields such as automotive, textiles, electronics, and aerospace.

Did you know? The first nylon was invented in 1935 by DuPont to replace silk in women’s stockings.

Type of PA | Common uses | Ideal injection temperature* | Advantages | Drawbacks |

PA6 (Nylon 6) | Mechanical parts, gears, automotive parts, textiles | 240–280 °C | Good balance price/performance, wear resistance, good chemical resistance | High moisture absorption, medium dimensional stability |

PA66 (Nylon 66) | Connectors, under-hood parts, electrical components | 260–300 °C | Higher rigidity than PA6, better heat resistance (up to 150 °C continuous) | More expensive, also absorbs moisture |

PA11 (biosourced) | Pneumatic tubing, marine parts, sports, medical devices | 220–250 °C | Flexible, excellent chemical resistance, very low water absorption, bio-based | High cost, limited availability |

PA12 | Fuel lines, low-temperature connectors, 3D printing | 180–220 °C | Very low water absorption, cold resistance, good chemical resistance | Less rigid, high cost |

PA46 | Engine parts, high-speed gears, high-temperature electrics | 300–330 °C | High melting point (295 °C), excellent wear and heat resistance | Very high cost, significant shrinkage |

PA6T | Electronic connectors, engine parts, >200 °C environments | 310–340 °C | High glass transition, low water absorption, dimensional stability | Requires copolymerization, costly |

PA9T | Miniature connectors, automotive electronics, chemical parts | 280–310 °C | Very low water absorption (0.17%), excellent chemical resistance, good hot rigidity | Expensive, less available |

PA10T | LEDs, solderable connectors, electronic components | 290–320 °C | Good rigidity, chemical resistance, low water absorption, solder resistance >280 °C | High cost, niche market |

*Indicative temperatures for plastic inside the barrel, to be adjusted depending on machine and mold.

Mechanical

High tensile and wear resistance

Thermal

Stability up to 150° for standards grades

Chemical

Resistance to oils, fuels, acids

Physical

Lightweight, good vibration damping

Aesthetic

Soft touch, wrinkle resistance

Automotive & Aerospace – Strategic Use

The automotive industry relies heavily on polyamide for bumpers, fenders, seats, and engine components. Its resistance to hydrocarbons and heat makes it a material of choice for under-hood parts. In aerospace, it is found in aircraft wings, ropes, and structural reinforcements.

Electronics & Electrical – Insulation and Performance

Connectors, cables, and electronic housings leverage polyamide’s insulating properties and strength. The hi-fi and telecommunications industries use it for its transmission quality and dimensional stability.

Textiles & Apparel – Versatility and Comfort

From technical clothing to stockings, shoes, and carpets, textile-grade polyamide combines durability and comfort. Its ability to blend with natural or synthetic fibers expands creative possibilities.

Defense & Safety – Protection and Reliability

Parachutes, military tents, bulletproof vests, and helmets exploit polyamide’s exceptional shock and abrasion resistance. Its light weight is a decisive advantage for wearable equipment.

Construction and infrastructure

Polyamide is used in electrical systems, plumbing hoses, pipes, and clamps. Its resistance to UV and weathering ensures long service life.

Food packaging

Polyamide containers use its gas-barrier properties and food compatibility. Its transparency and moldability make it popular in packaging.

Medical sector

Medical devices and prosthetics benefit from polyamide’s biocompatibility and ability to be sterilized without losing properties.

Sports, leisure, and marine applications: performance and sustainability

Snowboards, skis, canoes, musical instruments, sports mats, and sleeping bags benefit from the lightness and strength of polyamide, whose ability to absorb vibrations improves performance. Sails and fishing nets exploit its resistance to salt water and UV rays for exceptional durability in marine environments.

Everyday accessories

Eyewear frames, umbrellas, toothbrushes, and combs demonstrate polyamide’s wide range of consumer applications.

Plastic injection molding remains the most common process for polyamide. However, this material requires specific precautions: thorough drying beforehand to remove moisture, high melting temperatures (220–280 °C depending on grade), and careful shrinkage management during cooling.

Injection parameters must be finely tuned: high injection pressure to compensate for viscosity, extended holding time to reduce defects, and controlled cooling to optimize crystallinity.

Other processes include:

⚠️ Important: Polyamide easily absorbs moisture → drying is essential before processing. Moisture, shrinkage, and thermal degradation risks must be controlled to ensure final part quality.

Polyamide production, derived from petroleum through complex chemical reactions, is energy-intensive and generates a significant environmental footprint: polluting energy, toxic by-products, and pollution. Non-biodegradable, polyamide takes 30–40 years to decompose, and its incineration releases toxic fumes.

To address these issues, industry is exploring alternatives such as bio-sourced polyamides (PA11, PA10) and Econyl®, made from recycled nylon, reducing impact by up to 80% and water consumption by 90%. Mechanical and chemical recycling are advancing, although sorting fiber-reinforced grades remains challenging. These solutions still account for only about 2% of global production, and microplastics remain an issue even with recycled feedstocks.

Polyamide also has technical limitations (high cost, moisture absorption) that complicate its replacement. A responsible use strategy — reserving polyamide for applications where its unique properties are truly necessary — is recommended to balance performance with environmental responsibility.

The choice depends on service temperature, desired rigidity, water absorption, and chemical resistance. Reinforcements such as glass fibers improve rigidity, while some grades offer more flexibility or better moisture resistance.

Examples:

Polyamide can be processed very effectively on the manual HoliPress injection machine, provided some precautions are taken regarding its hygroscopic nature and high processing temperatures.

Concrete example: injection of PA6.6 into a resin 10K mold was successfully achieved. The material was heated to 290 °C, while the mold was kept at 110 °C to ensure optimal filling and minimize shrinkage.

For mold heating, two solutions are available: an oven or a pre-heating system integrated into the mold clamping setup. For the material, a heated nozzle can be added to the HP16+, or one can opt for the HP38, which comes equipped with it as standard.

This type of test highlights the need for precise temperature control, even during manual prototyping.

Another advantage: HoliPress also allows recycling of unused or sintered SLS powders, particularly for PA11 and PA12. These residual powders, often considered waste, can be reinjected into a manual prototyping cycle. This opens an interesting pathway to give a second life to costly materials while reducing waste.

Practical tips for injecting polyamide with HoliPress:

👉 In summary, manual polyamide injection with HoliPress is an excellent approach for rapid prototyping, educational experiments, and local recycling of technical materials.

All manufactured materials have an environmental impact, whether from emissions or recyclability challenges. While no full substitute yet exists for petroleum-based polyamide, promising bio-sourced alternatives such as PA11 are under development. Petroleum price volatility and climate awareness are likely to accelerate their adoption.

As an essential technical material, polyamide combines remarkable mechanical properties, processing versatility, and wide application scope. Its presence across all industrial sectors underlines its strategic importance.

But its impacts — energy-intensive production and microplastic pollution — require a rethinking of its use. Bio-sourced and recycled polyamides provide encouraging prospects, though their adoption remains limited. The future lies in optimized use where its properties are truly indispensable, along with the development of sustainable alternatives for other applications, through collaboration between industry, researchers, and policymakers.

For professionals, the challenge is to integrate environmental criteria into their technical choices today, anticipating regulations while maintaining performance.

Share on

À propos

HoliMaker est une entreprise innovante qui conçoit, produit et commercialise des outils de micro-industrie destinés à la transformation du plastique. HoliMaker propose également des ateliers et des formations à la manipulation de la matière.

HoliMaker est une startup de la Région Grand Est implantée dans le Sillon Lorrain.

Implantés à Metz en Moselle, HoliMaker préserve un savoir-faire local à travers son écosystème de fournisseurs Français, de fabricants de matériaux, de sous-traitants mais aussi de partenaires revendeurs.

Nous repoussons les standards de qualité et de savoir-faire. Toutes les pièces sont assemblées dans nos locaux

HoliMaker is an innovative company that designs, produces and markets micro-industrial tools for plastic processing. HoliMaker also offers workshops and training courses in material handling.

HoliMaker is a startup from the Grand Est region, based in the Lorraine region.

Based in Metz, Moselle, HoliMaker preserves local know-how through its ecosystem of French suppliers, material manufacturers, subcontractors and reseller partners.

We push back the standards of quality and know-how. All parts are assembled on our premises.