When developing a plastic piece, choosing the compound is only the first step. To ensure that the final product will be reliable, durable, and compliant with norms, it is essential to conduct plastic material testing. These tests help anticipate the mechanical behavior of the polymer, limit risks related to product liability, and strengthen customer confidence.

At HoliMaker, we manufacture machines that allow our clients to perform their own tests, easily and quickly, before launching large runs. We also provide standardized tensile specimen molds. This gives our clients the ability to send them to laboratories for tests compliant with ISO requirements.

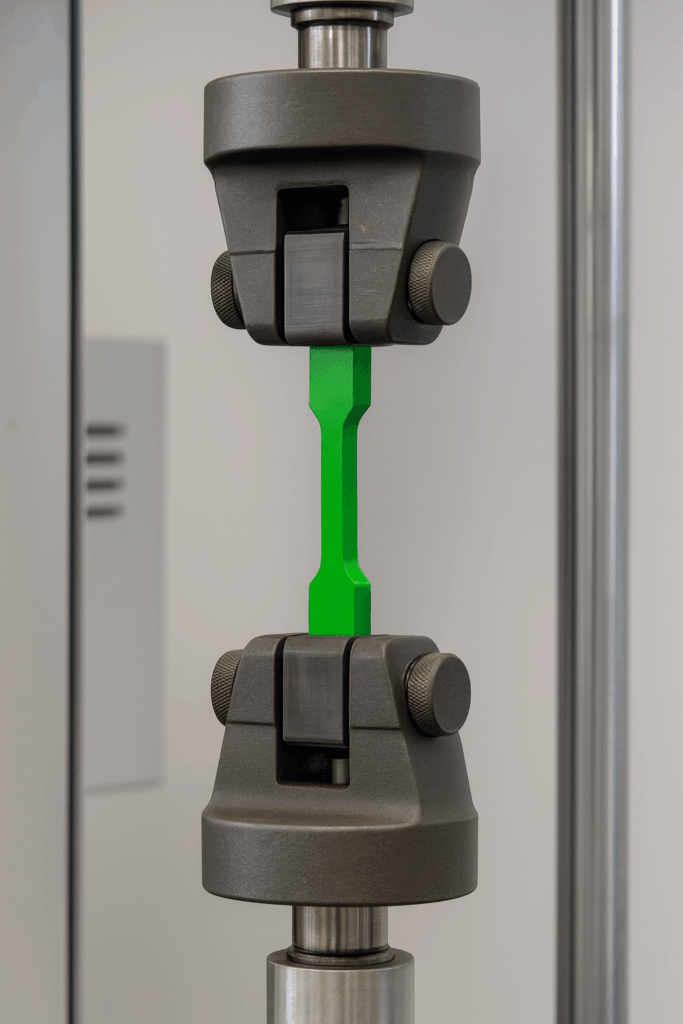

Each polymer has different characteristics: tensile strength, deformation, stiffness, creep resistance, and impact resistance. Tensile tests measure the maximum stress supported and the elongation it undergoes before breaking. These measurements are essential for predicting item longevity and ensuring its performance, especially for rigid parts or those subjected to significant stresses.

Before serial production, it is crucial to verify that the polymer remains consistent from one batch to another and that injected parts exhibit homogeneous properties. Initial tests on specimens allow you to:

This step is essential to guarantee the quality and reliability of your production.

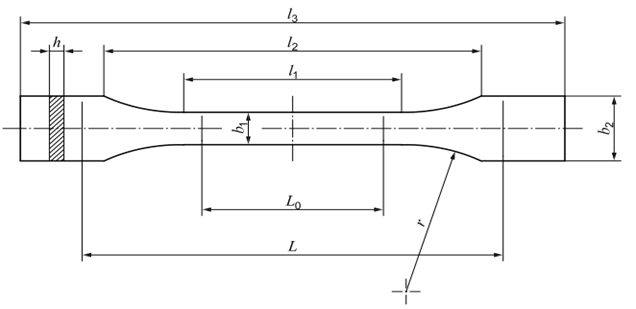

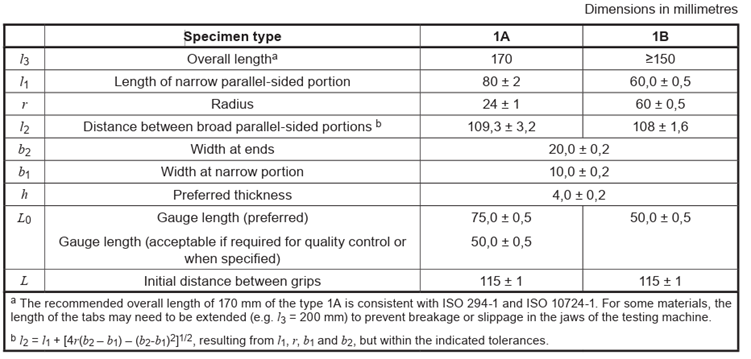

ISO standards, such as ISO 527-2, define standard methods for measuring the strength of plastics. They specifically specify:

HoliMaker manufactures molds for specimens compliant with the two most common types: Type 1A and Type 1B, meeting ISO requirements and ensuring data reliability.

Having documented tests, performed according to ISO standards, helps limit legal risks in case of failure. Reports include stress and deformation values and the nature of the material, serving as proof of due diligence for manufacturers.

Transparency about the mechanical performance and durability of a product increases your brand’s credibility. Customers appreciate products whose stiffness, deformation, and stress have been measured and verified according to recognized ISO specifications.

In addition to tensile testing, several tests help characterize a material:

These tests are complementary and provide a complete picture of the mechanical behavior of the plastic.

For tensile tests, the ISO 527-2 standard defines several types of specimens according to cross-section and length. The most common are:

These specimens allow precise measurement of:

At HoliMaker, with our HoliPress 16+ and HoliPress 38 machines, our clients can produce their own samples, ensuring homogeneity and compliance with ISO requirements.

Source: ITEH Standards

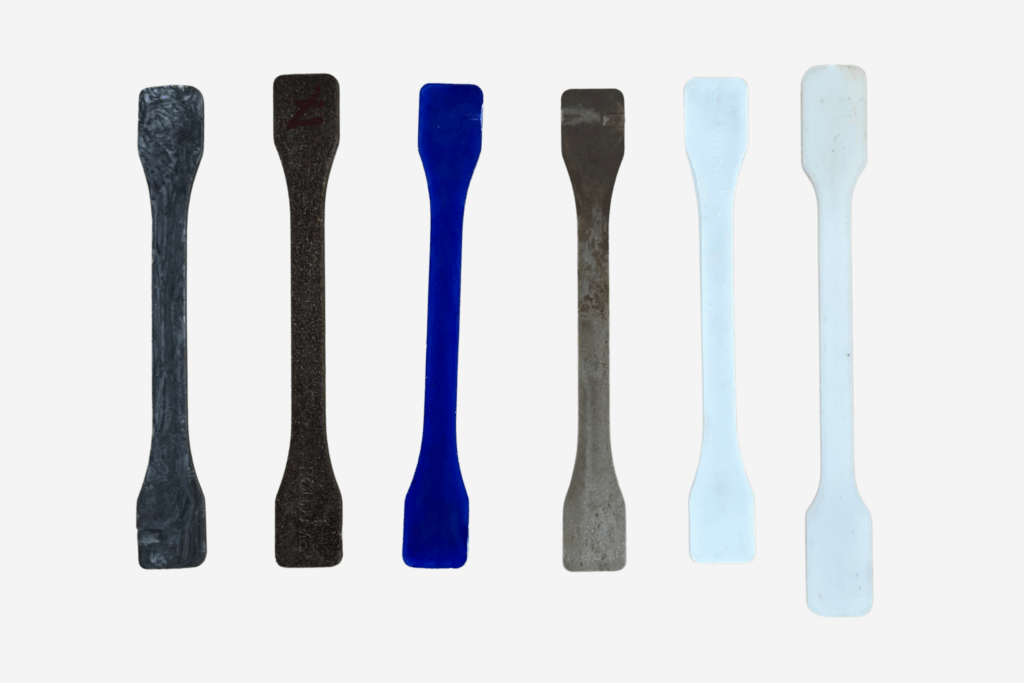

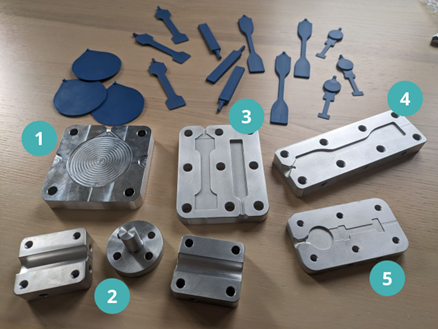

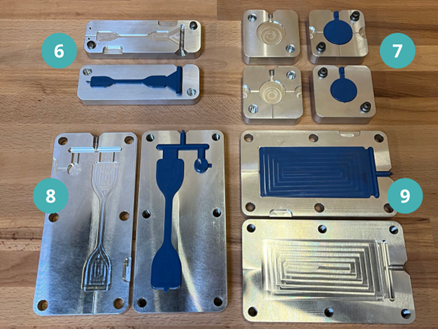

Other specimen molds can be manufactured to adapt to specific needs. The specimens illustrated below, primarily standardized, constitute examples of customer implementations:

N° | Type | ISO norm | Dimensions |

1 | Rheology disc | / | 60mm (d) x 1mm |

2 | Cylinder | ASTM D695 | - 12,7 mm (d) x 24,5 mm - 12,7 mm (d) x 50,8 mm |

3 | Rectangle & tensile | ASTM D882 | - 60,5 mm x 13 mm x 3 mm - 80 mm x 20 mm x 1 mm (calibrated part: 3,6 mm x 0,9 mm) |

4 | Tensile | ASTM D638 type IV | 115 mm x 19 mm x 3,4 mm (calibrated part: 33 mm x 6 mm) |

5 | Circle & tensile | ASTM D882 | 25,4 mm x 12,7 mm x 0,6 mm (calibrated part: 22 mm x 5 mm) |

6 | Tensile | ISO 527-5A | 75 mm x 12,5 mm x 2 mm (calibrated part: 25 mm x 4 mm) |

7 | Rheology disc | / | Custom |

8 | Tensile & circle | - ISO 37 type 1 - ISO 815B | - 115 mm x 25 mm x 2 mm (calibrated part: 33 mm x 6 mm) - 13 mm (d) x 0,5 mm |

9 | Rectangular plate | / | 105 mm x 70 mm x 4 mm |

Plastic material testing is an indispensable step in product development. It allows you to:

With HoliPress, HoliMaker offers machines that enable specimen production and preparation for regulatory testing. Investing in material testing means securing your projects and maximizing the performance of your plastic products.

Share on

À propos

HoliMaker est une entreprise innovante qui conçoit, produit et commercialise des outils de micro-industrie destinés à la transformation du plastique. HoliMaker propose également des ateliers et des formations à la manipulation de la matière.

HoliMaker est une startup de la Région Grand Est implantée dans le Sillon Lorrain.

Implantés à Metz en Moselle, HoliMaker préserve un savoir-faire local à travers son écosystème de fournisseurs Français, de fabricants de matériaux, de sous-traitants mais aussi de partenaires revendeurs.

Nous repoussons les standards de qualité et de savoir-faire. Toutes les pièces sont assemblées dans nos locaux

HoliMaker is an innovative company that designs, produces and markets micro-industrial tools for plastic processing. HoliMaker also offers workshops and training courses in material handling.

HoliMaker is a startup from the Grand Est region, based in the Lorraine region.

Based in Metz, Moselle, HoliMaker preserves local know-how through its ecosystem of French suppliers, material manufacturers, subcontractors and reseller partners.

We push back the standards of quality and know-how. All parts are assembled on our premises.