For Formnext 2025, we showcased a part that was fully designed, molded, and injected in-house: a cable clamp produced live at the show. The goal was simple: to demonstrate that it is possible to move quickly from design to production using a resin-printed mold, a HoliPress 38 manual press, and an industrial-grade material.

This part brings together several technical challenges in a single project: customization, undercut management, significant length, and real injection constraints. All of this had to be reliable enough to withstand several hundred cycles in a demanding environment such as a trade show.

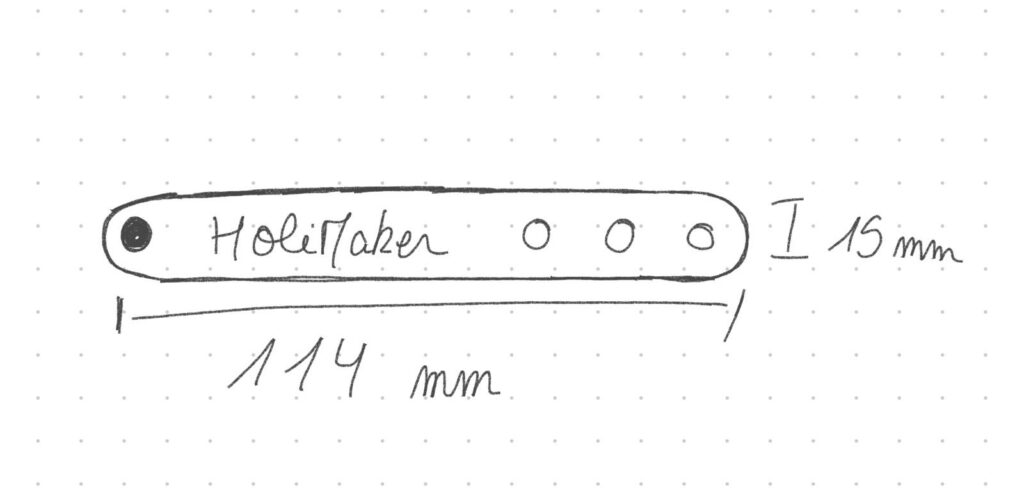

The part produced is a cable clamp designed to be customizable through an engraving system. This allows for modifications to markings, logos, or text without having to redevelop the entire mold. This approach enables rapid adaptation of the part for different applications or clients while maintaining the same mechanical base.

Dimensions, features, and material

The part has the following dimensions: 114 × 15 × 3 mm. The thickness at the button is 10 mm, with a total volume of 4.7 cm³. It is injected in TPS Kraiburg, a flexible material suitable for this type of application, offering both flexibility, strength, and long-term durability.

A technically demanding part

Two major challenges guided the design phase:

Results achieved

The part was injected using the HoliPress 38, supported by a hydraulic clamping system to ensure constant and controlled mold closure. In total, over 400 parts were produced in 4 days without mold damage. This result is particularly significant given the constraints of a trade show: high pace, temperature variations, frequent handling, and continuous public exposure.

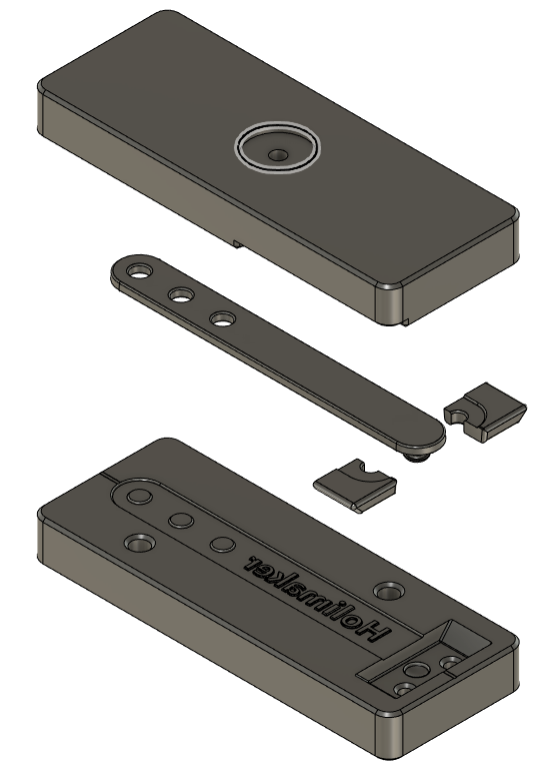

The mold was entirely designed and manufactured in-house. The goal was to demonstrate that it is possible to quickly produce a functional printed mold capable of withstanding real production—not just a few test cycles.

Mold dimensions: 130 × 50 × 30 mm.

The presence of the undercut on the button required the integration of slides into the mold. These inserts allow the undercut area to be released during demolding without excessive stress on the part or mold.

Two vents were placed at the ends to facilitate air evacuation and improve filling. Two notches were also added to simplify manual mold opening.

Special attention was given to draft angles and fillets. Walls are slightly inclined, and corners are rounded to smooth material flow, reduce turbulence, and ensure better filling. In general, clean fillets and consistent wall thickness are essential to prevent flow disruptions and improve final part quality.

Materials used for the mold

The main body of the mold was printed in Formlabs Rigid 10K. This material was chosen for its rigidity, dimensional accuracy, and heat resistance. It does not deform under pressure or heat. However, it is very rigid: excessive force will break the mold without gradual deformation.

Technical inserts were printed in Grey V5, used especially in the “mushroom” area corresponding to the undercut. This material facilitates demolding and reduces the risk of tearing.

Why not make the entire mold in Grey V5? This material tends to gradually deform under heat, causing dimensional drift, reducing material flow paths, and making injection increasingly difficult over multiple cycles. Combining a Rigid 10K body with Grey V5 inserts offers a good balance between rigidity, precision, and ease of demolding.

Problems encountered and technical solutions

Best practices implemented

Throughout the show, the systematic use of release agent secured injection cycles. Hydraulic clamping pressure did not exceed 150 bars to avoid excessive stress on the mold.

These injections at Formnext demonstrated that a resin-printed mold can withstand several hundred injections, even in a demanding environment such as a trade show.

The project perfectly illustrates the complementarity between a printed mold, our HoliPress machines, and the use of industrial-grade technical materials. This combination allows for speed, flexibility, and accessibility.

Next steps include further optimizing the inserts to speed up demolding, testing other resins or materials, and exploring even more complex geometries.

We offer material and shape testing for prospective customers to ensure our machine meets their application requirements. Please contact us for more information.

The STEP file of the part is available for those who wish to analyze it further.

À propos

HoliMaker est une entreprise innovante qui conçoit, produit et commercialise des outils de micro-industrie destinés à la transformation du plastique. HoliMaker propose également des ateliers et des formations à la manipulation de la matière.

HoliMaker est une startup de la Région Grand Est implantée dans le Sillon Lorrain.

Implantés à Metz en Moselle, HoliMaker préserve un savoir-faire local à travers son écosystème de fournisseurs Français, de fabricants de matériaux, de sous-traitants mais aussi de partenaires revendeurs.

Nous repoussons les standards de qualité et de savoir-faire. Toutes les pièces sont assemblées dans nos locaux

HoliMaker is an innovative company that designs, produces and markets micro-industrial tools for plastic processing. HoliMaker also offers workshops and training courses in material handling.

HoliMaker is a startup from the Grand Est region, based in the Lorraine region.

Based in Metz, Moselle, HoliMaker preserves local know-how through its ecosystem of French suppliers, material manufacturers, subcontractors and reseller partners.

We push back the standards of quality and know-how. All parts are assembled on our premises.