HoliMaker designs, manufactures, and assembles HoliPress plastic injection molding machines in France.

HoliPress machines are suitable for prototyping, plastics education, material testing, plastic waste recycling, and pre-production production.

Ensuring durability and ease of use, our plastic injection molding machines offer significant time savings and cost reductions, ensuring great versatility to meet and adapt to your needs.

Hybrid, robust, multi-material, and versatile, it’s perfect for creating your plastic parts. Go from idea to injection molding with HoliPress.

HoliPress removes the constraints of industrial standards, particularly in terms of mold reception, which gives it great freedom of design but also ease of use.

20 times faster than FDM 3D printing, the injected parts have a finish and mechanical strength approaching that of industrial plastic injection (equivalent tensile test). With your manual strength, you can produce a finished part every 3 minutes.

By injecting industrial material into granules, HoliPress allows you to produce test specimens to characterize the different types of materials and mass-produce your parts.

Switch from one plastic material to another without changing machines: it’s now possible with HoliPress. Material is fed quickly via the lever rotation system . The French manual injection press can melt and inject a wide range of plastic materials with extremely varied characteristics into molds.

HoliPress has been designed to control your maintenance costs. You can purge your HoliPress and clean the nozzle independently using the tools included in the Starter Pack. Because your safety is paramount, we also provide a PPE protection kit including a pair of safety glasses and thermal gloves.

HoliPress makes manual injection molding accessible: you can inject all plastic materials that are injected in industry at less than 320°C.

Our French manual press is an ideal machine for prototyping your parts, it allows you to test the injection of your materials, produce your parts in recycled plastic and also test your solutions in good material injection.

The fields of application of HoliPress are very broad: engineering and product design (mechanical parts, watches, automobiles, electronics, etc.), health and pharmaceutical industry, communication objects, games and toys, education and training.

The time between designing the object and manufacturing the part by injection is shortened thanks to HoliPress. Using 3D printed molds in-house reduces costs and lead times compared to metal molds machined by an intermediary (mold makers and injectors).

Our French manual presses complement the tools used in your prototyping ecosystem, including mold manufacturing using 3D printing, laser cutting, and CNC. You can verify and control each production step before production begins without compromising the quality of the parts produced.

You gain flexibility, time and cost.

Machining

Steel, aluminum, copper, dense wood

3D Printing

Resin or FDM 3D Printing

Laser cutting and engraving

PMMA, metals, dense wood

Materiel

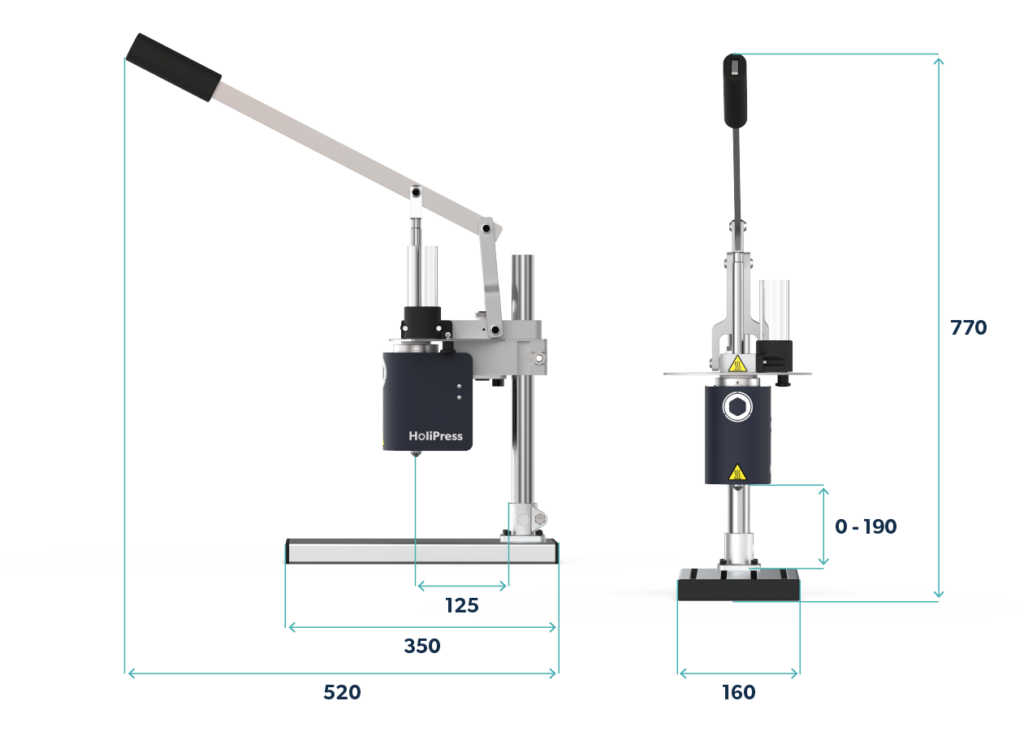

Holipress 16+

Height of the molds (in mm)

0 to 190

3 mm (5 mm available as an option)

5 mm (3 mm available as an option)

Shut-off nozzle / Standard nozzle

Technology

Maximum heating temperature

320°C

320°C

2 to 10 seconds

2 to 10 seconds

Power

3 to 6 minutes

Polymers

Filled polymers

Yes

Yes

Biocompatible

No (option available on request)

CE certification

Yes

Yes

Guarantee

Delivery, installation and handling package

Annual maintenance contract

Delivery by carrier

Whether you’re in a production workshop, a research lab, or a lab room, safety should be an important factor when choosing new equipment. Thanks to its robust, rugged, and insulated design, as well as the Personal Protective Equipment (PPE) included with our machine, HoliPress is completely safe to use.

We push the standards of quality and know-how by assembling all parts in our premises in Metz and choosing an ecosystem of French suppliers.

À propos

HoliMaker est une entreprise innovante qui conçoit, produit et commercialise des outils de micro-industrie destinés à la transformation du plastique. HoliMaker propose également des ateliers et des formations à la manipulation de la matière.

HoliMaker est une startup de la Région Grand Est implantée dans le Sillon Lorrain.

Implantés à Metz en Moselle, HoliMaker préserve un savoir-faire local à travers son écosystème de fournisseurs Français, de fabricants de matériaux, de sous-traitants mais aussi de partenaires revendeurs.

Nous repoussons les standards de qualité et de savoir-faire. Toutes les pièces sont assemblées dans nos locaux

HoliMaker is an innovative company that designs, produces and markets micro-industrial tools for plastic processing. HoliMaker also offers workshops and training courses in material handling.

HoliMaker is a startup from the Grand Est region, based in the Lorraine region.

Based in Metz, Moselle, HoliMaker preserves local know-how through its ecosystem of French suppliers, material manufacturers, subcontractors and reseller partners.

We push back the standards of quality and know-how. All parts are assembled on our premises.